At Spray-Net, we don’t just paint—we deliver factory-durable results that stand the test of time. The secret? It’s not one magic bullet, but multiple elements working in harmony: surface-tailored chemistry, specialized equipment, and a weather-smart process, all in tandem. This isn’t about selling paint to the masses; it’s a formulation-to-application model that fuses these three for consistent, high-quality outcomes to deliver the most cost-effective way to modernize a property. Here’s how that synergy makes the magic happen.

Three Pieces, One System: Chemistry, Equipment, and Process

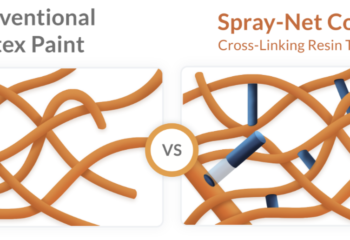

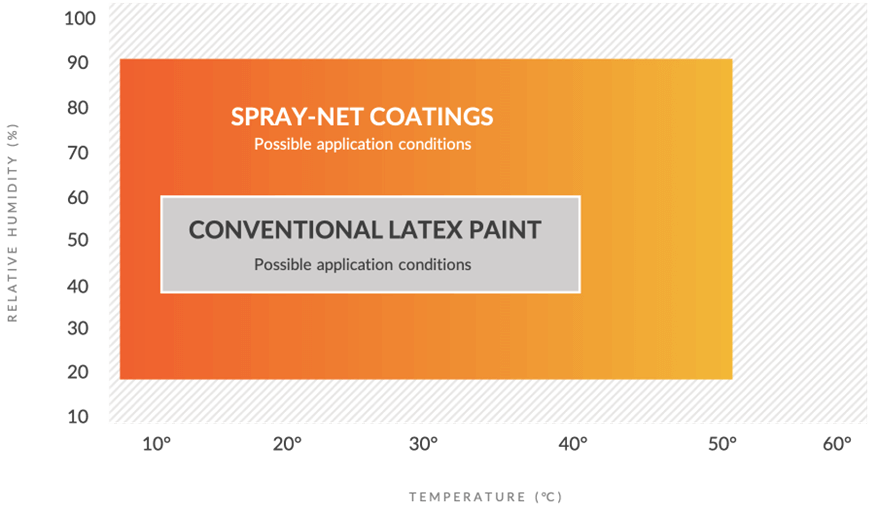

Chemistry is at the heart of what we do, but no single factor works alone—it’s the interplay that counts. Our coatings are custom-formulated for each surface, from stucco to vinyl siding, and designed specifically for our specialized equipment. That duo powers a process that adjusts to the weather, optimizing dry time for ideal film formation and a factory-durable finish. This integration earned our first patent, going beyond the limitations of conventional paints. Chemistry, equipment, and process—it’s all three, always together, never alone.

Chemistry Built for Surfaces, Backed by Equipment and Process

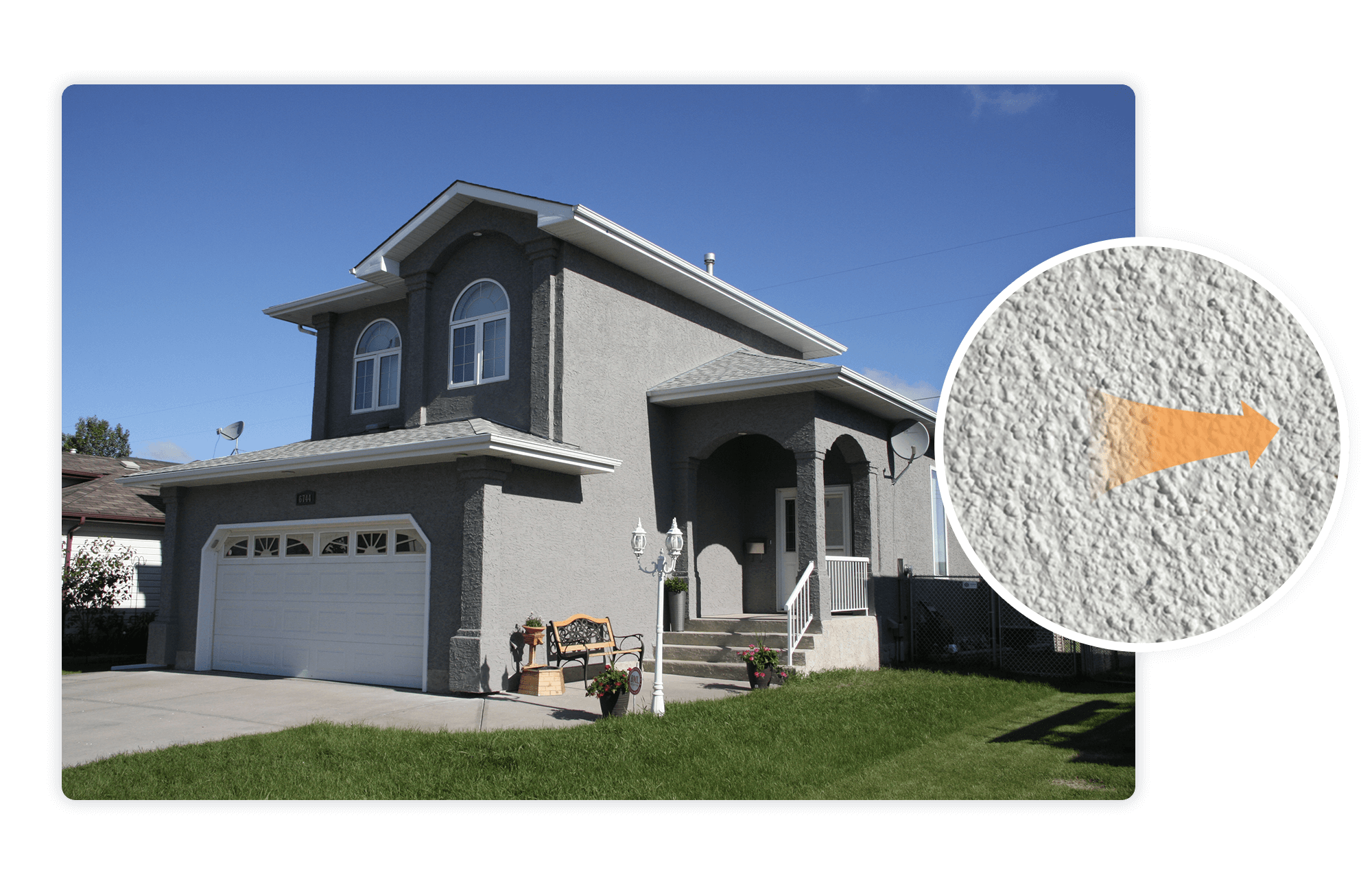

Our founder, a former conventional painter, ditched off-the-shelf cans when he realized their limits. Generic paints are a one-size-fits-all compromise—easy to apply, not built to last. We’ve crafted 13 proprietary chemistries, each tailored to a surface’s needs: scratch resistance for doors, washability for aluminum siding, breathable crack-bridging for stucco, our patented Vinyl Shield® for darker vinyl colors, or our brick stain. But the chemistry doesn’t stand alone—it’s formulated for our equipment and process, controlling all the key variables to ensure every coat performs. That’s the Spray-Net difference: consistency through integration.

Where the Trio Shines: Dry Time, Rheology, and Precision

The chemistry-equipment-process combo proves its worth in the details—dry time, rheology, and application precision all come together. Outdoors, adhesion and longevity hinge on hitting the dry-time sweet spot—too fast, no bond; too slow, imperfections creep in. But it’s more than that: our tailored chemistry, with rheology fine-tuned for specific thicknesses, ensures durability while leveling out for that flawless factory finish, all sprayed through specialized equipment in a weather-smart process. Indoors, it’s just as critical—kitchens get that same factory-durable finish in 1-2 days, with primer and topcoat synced to our system. Curious? Geek out here. It’s the three-pronged approach delivering, every time.

Years of Fine-Tuning the Trifecta

This didn’t happen overnight. Our founder sprayed over 500 homes himself, and we’ve since transformed more than 30,000 across North America’s varied climates. We’re always refining—chemistry, equipment, process—all locked in step. Why it works? Our formulation-to-application model. We don’t outsource; our Spray-Net-trained applicators are in-house, sharing insights to tweak rheology, dry times, and finishes. This closed-loop system ties the trio together and keeps optimizing the Spray-Net way.

Results for Every Homeowner

Whether it’s siding, brick, or cabinets, every job relies on this integrated system. The chemistry fits the surface, the equipment and our trained applicators apply it flawlessly, and the process seals the deal—delivering a finish that’s as tough as it is beautiful, every time.

It’s decades of expertise, a team that knows coatings inside out, and a model that fuses formulation with application. Chemistry, equipment, process—they’re not separate; they’re one system, built to work as a unit. That’s custom chemistry for smarter painting—our slogan, and the promise we keep.

Subscribe to our blog & newsletter.

This is the advantage of subscribing to our blog.