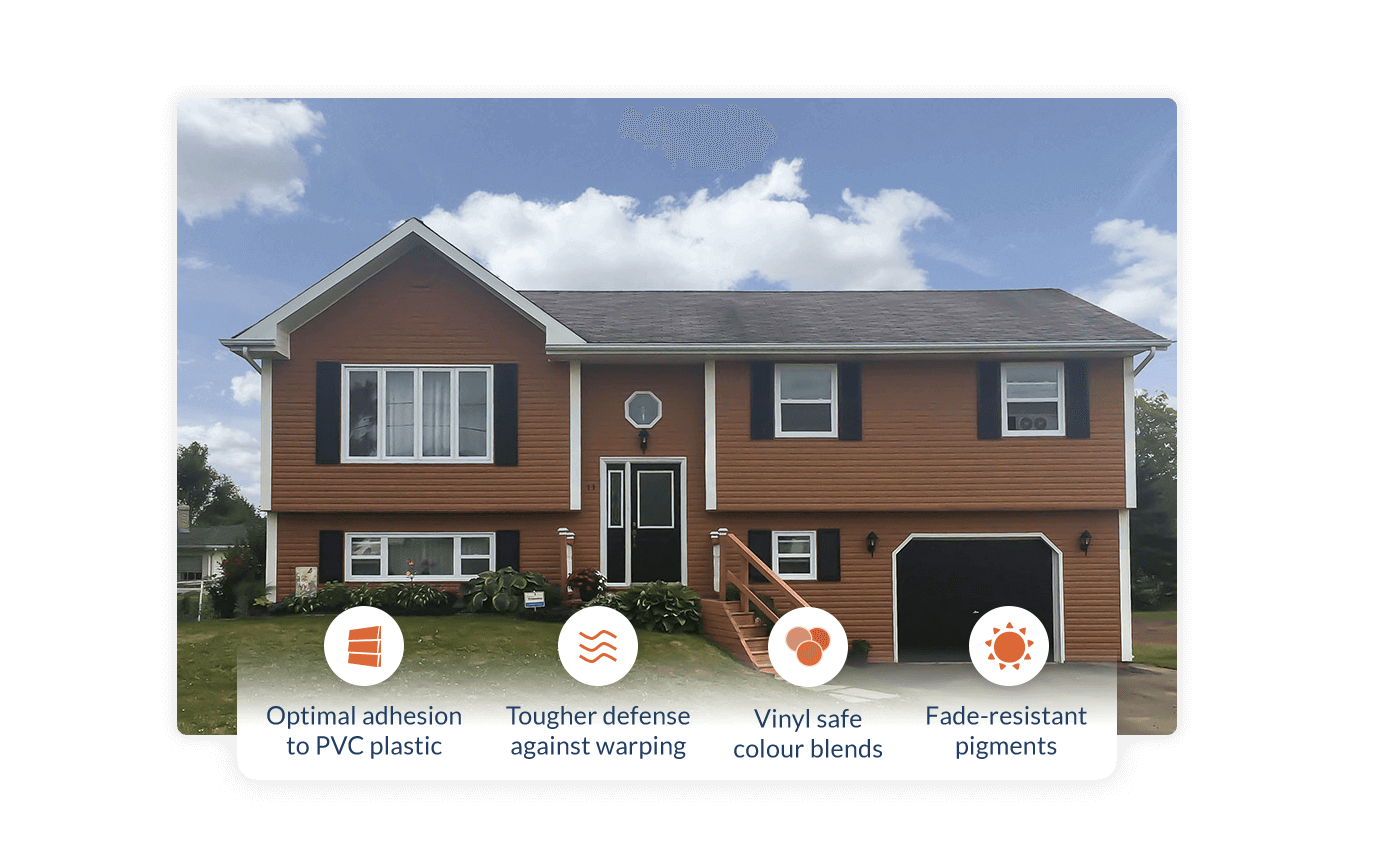

Yes! It’s safe to paint your vinyl siding.

Vinyl siding is made from plastic, which most paint is not made to adhere to and also heats up a lot quicker than other surfaces, causing fading and even worse, warping. That’s why we custom-formulated a strategic paint for vinyl with a solar-transparent shield and created an innovative patented process that zeros in on the unique composition of vinyl. Now, you can update the look of your vinyl and boost your home’s curb appeal without all of the worry.

Learn more

Our patented process determines the right way to paint your vinyl siding

We’ve seen that painting vinyl siding the right way requires several steps before you can even get to the paint part. Our patented process involves measuring the thickness and composition of your vinyl to determine a made-to-measure coating and colour solution to ensure long lasting durability and protection against warping.

![]()

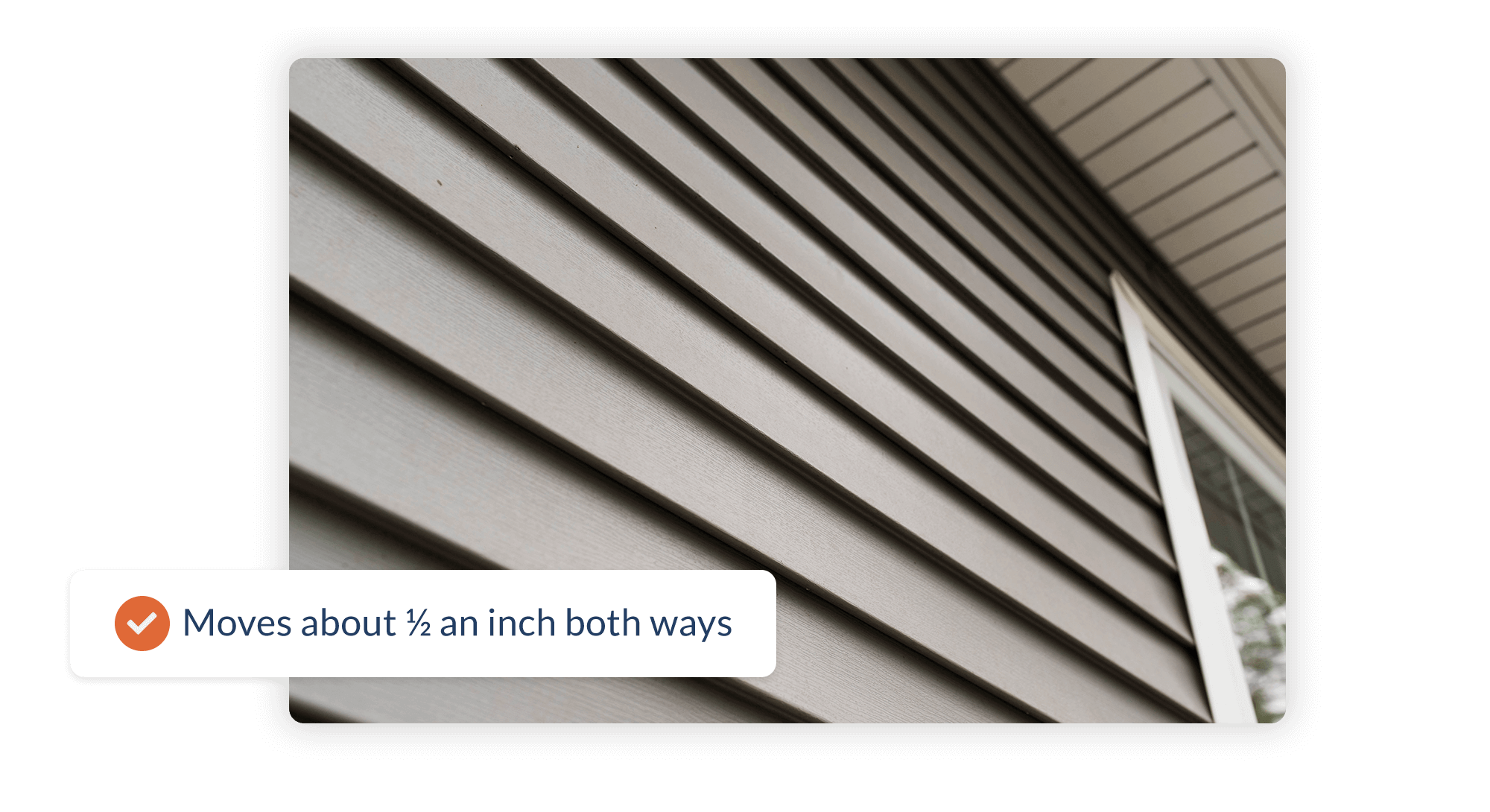

Proper installation is a must for a long-lasting paint finish.

Vinyl expands and contracts with temperature changes, so it has to be able to move. If your vinyl is nailed in too tight, it restricts movement of the siding and causes strain that can lead to warping and buckling… even on original, unpainted vinyl! We’ll evaluate the installation of your siding during your at-home consultation to make sure it’s set up for the proper painting conditions.

Frequently asked questions about how it works.

Is Spray-Net the only one on the market who can paint on aluminum and vinyl siding, stucco and hardie-board, front and garage doors, windows, and brick?

Spray-Net isn’t the only company that paints aluminum and vinyl siding, stucco, hardie board, doors and windows, or brick. However, through years of research and rigorous testing and working with paint chemists, we have created custom formulations for each specific application. We can confidently offer a 15-year no-peel warranty on all of our applications with our custom coatings and patented process. Spray-Net is the only company delivering a factory durable finish on each of these surfaces, as it’s the only thing we do, all day, every day!

What types of Exterior surfaces do you paint?

We paint:

- Aluminum, fiber cement, vinyl, and engineered wood sidings

- Brick

- Stucco and aggregate

- Front and garage doors

- Windows

- Soffits, fascias, and gutters

These surfaces will be coated with paints customized according to the material and weather. The paints allow for durability, washability, UV resistance, high-traffic scratch resistance, and flexibility.

Do you offer a wide variety of colors?

We have a wide variety of colors for you to choose from, each specifically formulated for exterior use and formulated with optimal fade resistance in mind. We use a combination of the most popular standard siding and door and window colors to provide maximum durability against premature fading and discoloration, as well as to apply the finishing touch of matching-colored caulking.

Although we can match any exterior paint color you have in mind, we can’t always provide the same optimal fade resistance or a matching caulking color. Finally, we work with an experienced designer every year to help us come up with the latest color trends and ultra-stylish exterior color palettes… an added perk that our customers really appreciate!

Why can’t you paint a surface that has already been repainted?

We offer homeowners a permanent factory finish that serves as an alternative to replacement. If we can’t fulfill this promise to you, then we simply don’t take on the project. Delivering on the Spray-Net promise is very important to us. In the case of brick, if pores are already saturated with a coating, it’s virtually impossible for the brick to absorb our stain. Like stripping wood, the time needed to strip paint off aluminum and vinyl siding is indeterminate. It can actually take DAYS to completely remove several coats of paint. If a project takes days, then it’s not likely to be cost-effective.

“Just paint over it” you say? Well, if we paint over an existing coat of paint, the aggressive nature of our coatings to maximize adhesion might actually pull away at the less-resistant latex paint. If the original paint film comes off, then the outermost coat of paint (ours) would also come off with it.

How many coats of paint do you apply?

Unlike the traditional brush and roller method, spray-applied painting is measured according to paint thickness rather than the number of coats. Depending on the specific exterior coating that we’re using, paint thickness can vary between 4 and 20 mils. A thicker paint film doesn’t automatically mean it will be more durable; it all depends on what we’re trying to achieve for a final product’s properties.

You can be sure that our expert painting crews are equipped with the knowledge, products, and experience to produce a permanent factory finish… every time.

What’s the finish of your exterior paint?

For aluminum and vinyl exterior siding, we strike the perfect balance between a matte and glossy finish to minimize the appearance of surface imperfections and to create a like-new washable finish. These types of custom finishes are not available with conventional paints limited to matte, satin, or semi-gloss. For doors and windows, we follow the same gloss standards as the door and window industry so that they look like they’ve just arrived from the factory!

What kind of products do you use?

We are an eco-friendly painting company that uses our own exclusive line of low VOC, water-based, and industrial-strength exterior paints and coatings. All of our products fall under all government VOC limits. Each of our exterior and kitchen paints and coatings are uniquely tailored for each surface and for a specific method of application, and they all contain a unique blend of additives and superior inorganic pigments that allow us to achieve the desired results per surface that we’re revamping!

Since factory paint is “baked,” is your paint as scratch resistant?

When painting doors and windows for manufacturers, IR lamps are used to artificially accelerate the curing process. This specific technique is necessary since the demands of the commercial market require quick packaging and delivery of products. To bring the same one-day permanent factory results to the residential sector, we’ve formulated our exclusive paints and coatings so that they become dry to the touch within 15-30 minutes of application, depending on the weather. In a short time, the paint film achieves a factory OEM level of hardness. With the help of the sun’s natural UV rays, the paint fully cures and achieves maximum hardness and durability in the days that follow. The sun’s natural UV rays are just as effective as a forced factory cure. When needed in unideal weather conditions, however, we can produce a forced bake for front doors in our mobile spray booth, since this high-traffic surface requires a quicker full cure. Our industrial grade formulations coupled with an optimal application process is what allows our coatings to be as scratch and mar resistant as factory coatings.

What’s the difference between spray-applied paint and electrostatic paint?

Most people confuse the difference between spray-applied paint and electrostatic paint. Electrostatic paint is typically oil-based and is commonly used in the industrial sector to paint difficult to paint shapes, like cylinders. These objects need to be made of a high conducting metal such as steel. Using an electrical charge, paint is propelled toward the surface to create a perfect even finish. This isn’t necessary (or possible) in the residential sector because we use non-toxic water-based products and the surfaces that we revamp have very little to no conductivity so it wouldn’t work anyway. The water content of our products, as well as the painting of mostly non-metal surfaces, wouldn’t allow for a sufficient electrical charge. The big appeal of electrostatic painting is the low-overspray property of the technique, but all of our paints and coatings are specifically designed for spray application. Combined with our spray equipment, this technique results in a high transfer efficiency and minimal amount of overspray. When it comes to painting the exterior of a home, we’ve formulated the ideal products and have mastered the optimal techniques to deliver a like-new and durable factory finish.

Discover the benefits of our exterior painting services

We’ve made sure this is the only kind of exterior painting you’ll ever need.

Need another reason to choose Spray-Net?

Make your choice!