Painting your cabinets is a big decision, and the kitchen cabinet paint you choose can make or break the outcome. With so many options out there, it’s easy to feel overwhelmed. Should you go with a pre-catalyzed lacquer? A urethane? What about 2-component polyurethanes—and do isocyanates matter? In this guide, we’ll break down the main types of kitchen cabinet paint, explore their strengths and weaknesses, and explain our customized approach to cabinet paint formulation at Spray-Net.

Types of Cabinet Paints: A Quick Rundown

Not all cabinet coatings are created equal. Here’s a look at the most common types and what they bring to the table:

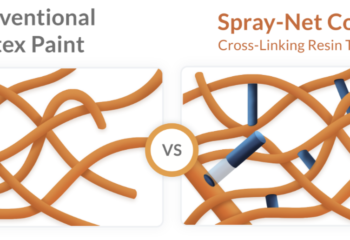

1. Regular Acrylic Latex Cabinet Paints

- What They Are: Widely available single-component (1K) water-based paints, often marketed for DIY cabinet projects. Made from acrylic resins, they dry through evaporation without a chemical hardener.

- Pros: Affordable, easy to apply with a brush or roller, low-VOC options available, and quick cleanup with soap and water—can be used for a temporary refresh.

- Cons: Not on the same level as more tailored or industrial coatings (more on those below); they lack durability, scratch resistance, and stain protection, often wearing or peeling under kitchen use. For short-term DIY fixes, not lasting solutions.

2. Pre-Catalyzed Cabinet Paints

- What They Are: Single-component (1K) finishes with a hardener pre-mixed into the formula. Think of them as an upgraded lacquer or varnish.

- Pros: Easy to apply, quick-drying, and widely available.

- Cons: Less durable than 2-component options, wearing down faster under heavy use—less ideal for busy kitchens or bathrooms.

3. Urethane Cabinet Paints

- What They Are: Single-component (1K) coatings known for toughness and resistance to moisture and wear. Unlike 2K systems, they don’t require a separate hardener and cure through air exposure.

- Pros: Often stronger than pre-catalyzed options, offering decent protection against scratches and stains, and easy to apply without mixing.

- Cons: Lacking the chemical reaction of 2K systems, 1K urethanes don’t achieve the same hardness or longevity, making them less durable under heavy use.

4. Two-Component (2K) Polyurethanes Cabinet Paints

- What They Are: Coatings that combine a resin base with a hardener, triggering a chemical reaction for a super-durable finish. They come in two types:

- With Isocyanates: The hardener contains isocyanates, a chemical that boosts hardness.

- Without Isocyanates: Alternative hardeners achieve durability without isocyanate health risks.

- Pros: Exceptional hardness, chemical resistance, and longevity—perfect for a factory-quality finish.

- Cons: Vary by formulation (see the isocyanate debate below).

Most 2K polyurethanes dominate the cabinet coating market because they’re formulated for factory application—think industrial spray booths with controlled conditions. Taking these factory products and using them on-site might seem logical, but they’re not designed for it, often making them impractical and unsafe in homes. At Spray-Net, we’ve flipped the script by custom-engineering our 2K polyurethane coatings specifically for on-site use. Here’s why that matters.

The Isocyanate Debate: Pros, Cons, and Trade-Offs

Isocyanates are a key ingredient in many factory-grade 2K polyurethanes, but they’re a double-edged sword. Here’s the breakdown:

Pros of Isocyanates:

- Extreme Hardness: Scoring high on the ASTM D3363 hardness scale (often 2H or harder), they resist scratches and wear.

- Durability: They create a tough, long-lasting finish—standard in industrial settings.

Cons of Isocyanates:

- Brittleness: That hardness can make coatings brittle, leading to chipping or cracking on cabinets that flex with temperature changes or daily use.

- Safety Risks: Isocyanates are hazardous—releasing high VOCs that can irritate eyes and lungs or trigger severe allergic reactions, even asthma, with prolonged exposure. It’s not just during application; as these coatings cure, off-gassing releases harmful chemicals and odors into your home. Factory ventilation manages this; your kitchen can’t.

- Known carcinogen: Beyond immediate irritation to eyes and lungs, isocyanates are classified as known carcinogens by agencies like the International Agency for Research on Cancer (IARC), linked to long-term health risks like lung cancer with repeated exposure. At Spray-Net, we’re committed to eliminating these dangers—not just for our customers, but for our staff too. Prolonged exposure during application and curing poses serious risks to applicators, and we believe a safe work environment is non-negotiable. By keeping our team healthy and protected, we ensure they can deliver the exceptional service our customers deserve—a win-win for everyone.

- Not for On-Site Use: These products are formulated and best suited for factory application and aren’t meant for homes. They’re designed to be sprayed with air guns (high overspray), thinned, and applied in multiple coats—optimized for controlled factory environments, not on-site conditions. On-site application—and curing—leaves lingering odors and health hazards, far from ideal for your family.

At Spray-Net, we recognized these flaws and built a better solution. Our 2K polyurethane cabinet paint ditch isocyanates, focusing on safety and flexibility while maintaining top performance.

The Spray-Net Approach: Safety Meets Smarter Painting

Our philosophy is clear: a cabinet coating should be as safe as it is strong. We’re not in the business of selling paint—we’re in the business of providing homeowners with a like-new kitchen at a fraction of the cost, time, and mess. That’s why we’ve engineered a proprietary 2K polyurethane that skips isocyanates and uses surface additives to supplement for the perfect balance—formulated explicitly for on-site application.

Here’s how:

- No Isocyanates, No Worries: Our low-VOC kitchen cabinet paint formula eliminates hazardous chemicals like isocyanates, ensuring your home stays safe and odor-free. Unlike factory coatings that off-gas harmful chemicals as they cure, our process prevents lingering odors or toxins—see how here. Plus, all our coatings fall well below the EPA’s low-VOC threshold of 380 g/L—cabinet primers under 100 g/L and topcoats under 150 g/L—minimizing exposure risks even further for a healthier indoor space.

- Why Low VOCs Matter: The EPA sets this limit to protect your health and the environment—VOCs, beyond just isocyanates, can have adverse health effects. By keeping our coatings below this standard, Spray-Net mitigates these risks, safeguarding your family, our team, and the air we all breathe.

- Hardness Meets Flexibility: Per the ASTM D3363 scale, our coatings hit 2B to HB—tough enough for nicks and scratches, flexible enough to avoid the brittleness and chipping of isocyanate finishes.

- Stain and Chemical Resistance: Tested to KCMA 9.4 standards against ketchup, coffee, olive oil, and wine, we score consistent 4s and 5s (on a 5-point scale)—proof our cabinets resist spills without staining.

- Built for Homes, Not Factories: Unlike factory-focused coatings, ours thrive on-site. We test our coatings on thousands of jobs across North America, continuously improving our formula based on direct feedback from our applicators. This hands-on approach—from formulation to application—ensures durability across climates and real-world conditions.

- Custom Application: Our primer doubles as a basecoat—smoothing imperfections, enhancing adhesion, and blocking stains. Matched to our topcoat’s flexibility, it prevents cracking, working seamlessly with our process and equipment for consistent results on every kitchen we transform.

The result? A finish that matches isocyanate durability without the risks—hard, flexible, and safe from application through curing, backed by real-world testing and refinement.

The Spray-Net Difference

So, what makes Spray-Net the best choice for your cabinets? It’s not just our coating—it’s the whole system working together. At the end of the day, our proprietary, customized chemistry is tailored to the equipment we use and coupled with our finely tuned process. This synergy allows us to deliver on our promise: a like-new kitchen for a fraction of the cost, time, and mess of replacement. Quick, cost-effective and no lingering odors.

- A Complete Solution: Our 2K polyurethane isn’t an off-the-shelf product—it’s designed to work synergistically with our sprayers, our primer, and our applicators, ensuring consistent factory-quality results right in your home.

- Proven Performance: Tested and refined across thousands of kitchens, our approach guarantees durability, safety (no isocyanates, no VOCs above the EPA’s 380 g/L low-VOC limit—cabinet coatings stay under 150 g/L), and resistance to daily wear—exceeding KCMA standards every time.

- Homeowner-First Results: We’re not here to simply sell paint; we’re here to transform your space. The combination of our chemistry, equipment, and process makes the magic happen—delivering a stunning, long-lasting finish with minimal disruption, often in just one day.

When choosing a cabinet paint, durability, safety, and practicality matter. With Spray-Net, you get all three, wrapped in a system built from the ground up to work synergistically for your home. It’s this holistic approach that sets us apart—because a great kitchen isn’t just about the paint, it’s about the promise we keep.

Want to see how we guarantee an odor-free, zero-VOC kitchen? Check our process here.

Subscribe to our blog & newsletter.

This is the advantage of subscribing to our blog.