Imagine you just painted your 1990’s oak wood cabinets in Chantilly Lace, the perfect shade of white that can brighten up and modernize the look of any kitchen. You wake up in the morning and eagerly head toward your kitchen to admire its fresh new look. Just as your dream of having a white modern kitchen starts to become a reality, you look at your newly painted kitchen cabinets and discover that newly formed yellow, blotchy stains have turned your kitchen renovation dream into a nightmare.

Frustration sets in – what is this unsightly, annoying culprit, and how can you fix your paint job? Welcome to the world of tannin bleed, a complex phenomenon rooted in wood chemistry that can ruin the paint finish on your kitchen cabinets, and completely degrade the entire look of your kitchen. But fear not! In this blog post, we’re here to give you the pro lowdown on what tannin bleed is, why it happens, and how you can avoid it, ensuring your kitchen cabinets stay beautiful and stain-free.

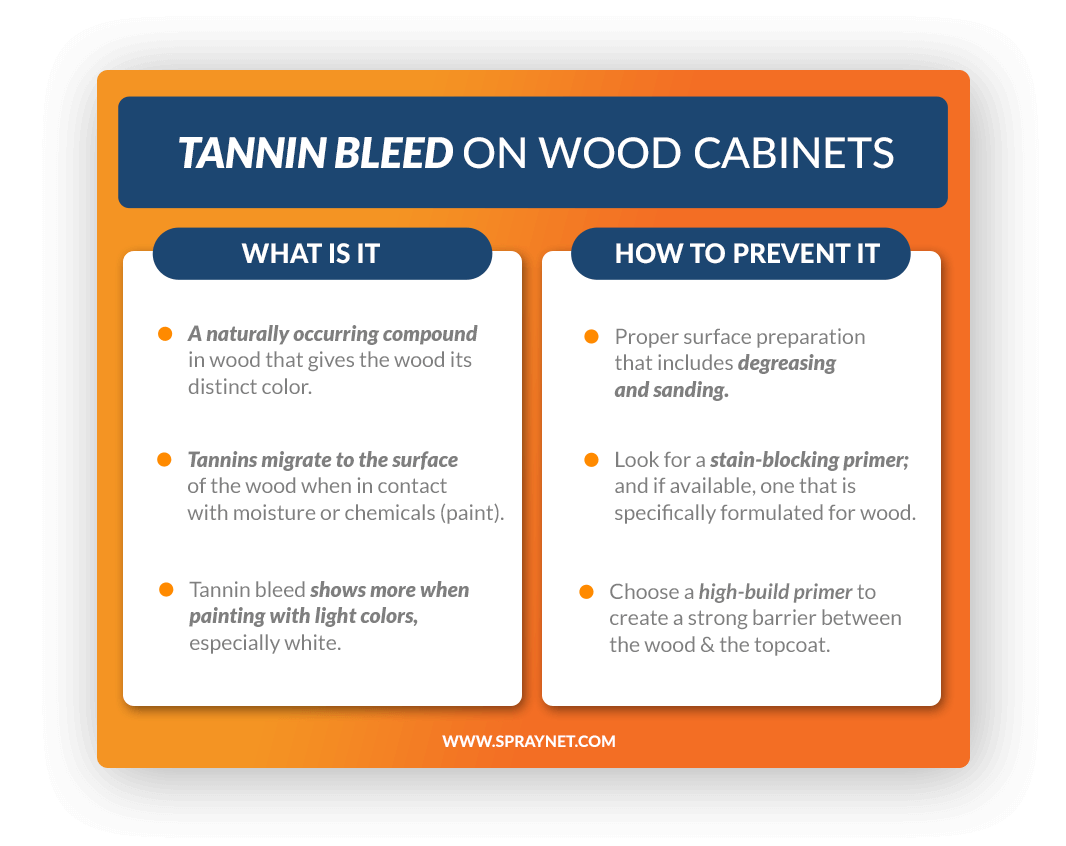

What is Tannin Bleed and How Does it Happen?

You know how wood has a natural brownish hue? Well, that’s where tannins come into play. Tannins are natural compounds present in wood that give it that color. Think of them as the wood’s distinctive signature. Tannins are found in woods like oak, cedar, redwood, and mahogany.

Now, let’s say you’re all set to apply a fresh coat of paint on your oak wood cabinets, which you’ve worked endlessly to repair, prep, and prime. You finally paint away, feeling accomplished. But a few days later, you notice brown or yellow spots starting to appear through your paint job. This is called tannin bleed.

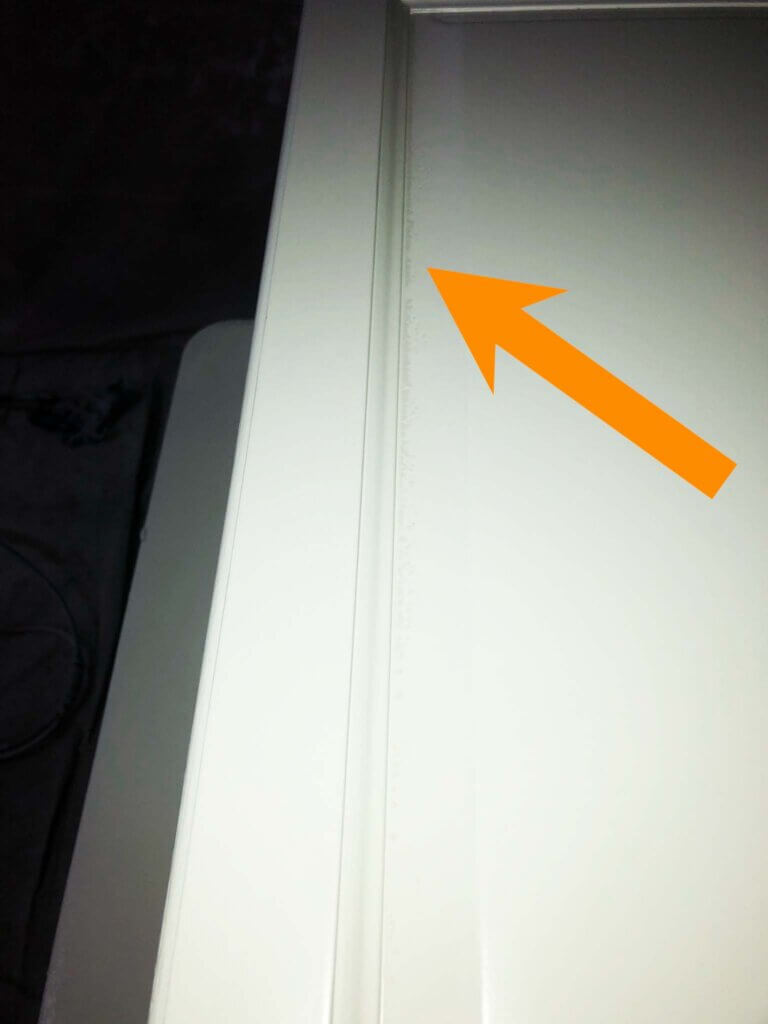

Sometimes referred to as “wood bleed,”or “bleed through,” tannin bleed happens when the tannins present in wood migrate to the surface, leading to stains and discoloration of the paint film. It happens when the tannins in the wood interact with moisture or specific chemicals (like paint). The tannins are essentially released and find themselves on the surface of the coated wood, resulting in yellowish stains or blotches. Tannin bleed shows up more when using light colors, especially white.

Tannin bleed can be quite frustrating, especially since a white kitchen never goes out of style and is a common shade used for most kitchen makeovers. Luckily, there are some things you can do to prevent tannin bleed from occurring.

How to prevent tannin bleed on wood cabinets

While it may seem impossible to combat tannin bleed when you’re painting oak cabinets, the right products and process can successfully prevent tannin bleed.

- Degrease: Before sanding, it’s important to cleanse the surface of any grease or surface contaminants that may prevent the coating from properly adhering to the wood. Cleanse the surface using an acetone-based surface preparation solution. This should be done before sanding, so you don’t spread and push those contaminants even deeper into the pores of the surface.

- Sand: thoroughly sand the wood to smooth out any surface imperfections and to create the necessary microscopic grit for the coating to “grip” onto.

- Repair: address any surface imperfections like cracks or knicks.

- Remove Dust: vacuum all dust to ensure a clean surface area for painting.

- Acetone Cleanse: wipe down the surface one last time with your acetone cleansing solution before priming.

- Prime: prime the wood cabinets with a stain-blocking primer that is specifically formulated for wood to neutralize the tannins. Look for primers with labels that say “stain-blocking” or “tannin-blocking.”

- Apply Topcoat: once your primer is completely dry, apply your topcoat.

Understanding the role of a primer in preventing tannin bleed

Choosing the right wood primer is key in preventing tannin bleed. The role of a primer is two-fold:

- Neutralize Tannins: stain-blocking primers contain special additives that go to battle with tannins by neutralizing them. This means that that the primer alters the chemical composition of the tannins in a way that stops the tannins from causing discoloration and stains on the surface.

- Block Tannin Migration: primers essentially seal the surface and create a protective shield between the wood and the paint. This creates a barrier that prevents the tannins from migrating to the surface.

Which primer is the best for preventing tannin bleed?

During our research and development phase of painting wood kitchen cabinets, we tested the leading stain-blocking primers on the market and experienced the following:

- BIN: we gave it a 7/10 for its tannin-blocking abilities, but its shellac-based, brittle nature didn’t fulfill our desired flexibility profile (a coating should be flexible to resist cracking and chipping).

- Cover Stain: while this oil-based option offered flexibility that was more compatible with our topcoat, we gave it a 5/10 for its tannin-blocking ability. Another drawback was its lengthy recoat time of over 2 hours.

- Stain Blocking Primer: by far the best option with a tannin-blocking ability of 8/10. It resulted in a decent flexible finish, but in terms of application, resulted in sagging.

Our verdict? If we had to pick a commercially available stain-blocking primer that can prevent tannin bleed for the average DIY project, it would be the General Finishes Stain Blocking Primer. It’s tannin-blocking power was the strongest and resulted in a more flexible finish than the other contenders.

Spray-Net’s Proprietary Wood Primer: The Best Way to Block Tannin Bleed

Many of our clients have older oak wood kitchen cabinets that were popular in the 90’s and, while still in great shape, just need a fresh coat of paint to give them a more contemporary look. So, we knew we had to formulate a high-performance primer that could effectively block unsightly tannin bleed, especially when using light colors like white.

Our proprietary, anti-tannin-bleed primer results in a stain-free finish with zero discoloration on wood cabinets.

- It is strategically formulated for wood and therefore, effectively neutralizes the tannins in the wood to prevent them from showing up on the painted surface.

- It contains anti-sag properties to prevent drips during application, resulting in a flawless and smooth finish.

- It dries to a flexible finish that is compatible with the flexibility of our topcoat and can effectively expand and contract to prevent cracking and peeling.

- It dries to an ultra-smooth finish with no bumps or texture to maximize the performance of the color topcoat without affecting final gloss or texture.

- Its hide build consistency not only fights tannin bleed but effortlessly fills in all grain, pores and even micro-cracks in the wood. The grain hiding power of our primer is especially beneficial for homeowners looking to hide grain in old wood cabinets for a more modern look.

The combination of our high-performance primer and our strategically formulated kitchen cabinet topcoat results in a finish that exceeds all Kitchen Cabinet Manufacturers Association (KCMA) standards.

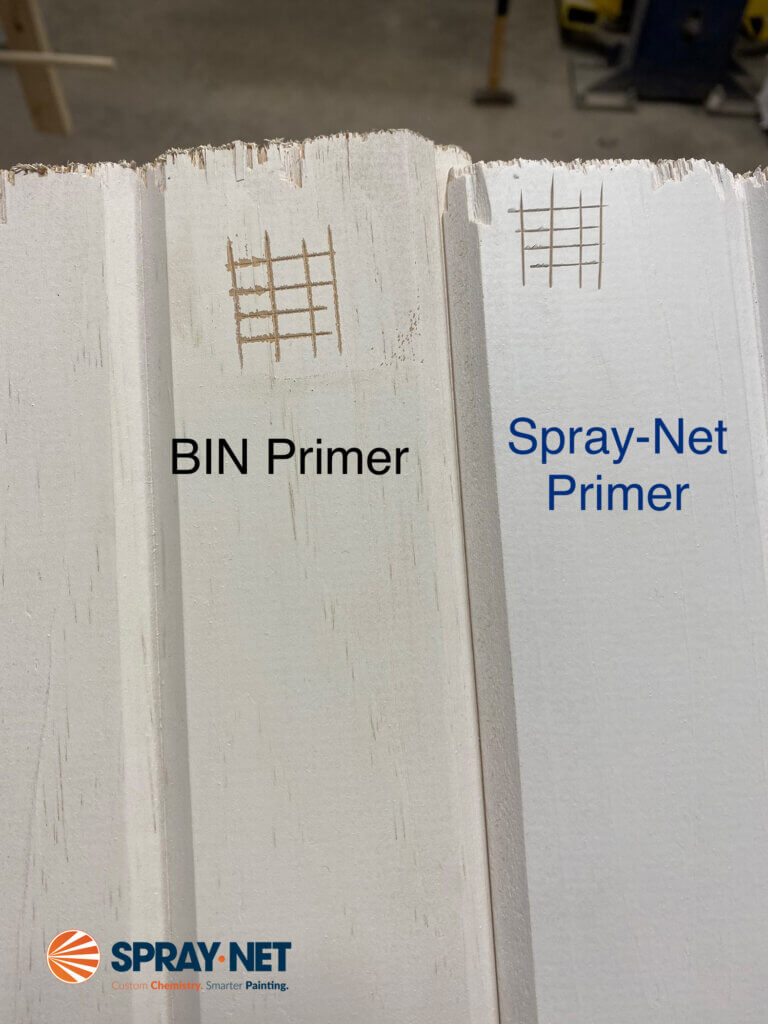

Testing the Spray-Net Wood Primer V The Leading Conventional Primer:

To test the performance of our kitchen cabinet primer against the leading conventional cabinet primer on the market, we performed a crosshatch test. A crosshatch test involves making crisscross cuts through the paint film with a sharp tool, kind of like making a grid. Then, you apply a piece of tape across the cross hatch and give it a quick pull.

The purpose of a cross hatch test is to determine the strength of the coating and its adhesion power. If the paint film is compromised, flakes off or chips in any way, this indicates a weak paint film with subpar adhesion that will eventually lead to failure: peeling, chipping etc. If the paint film stays put and remains intact, that’s a win.

The results:

After ripping off the piece of adhesive, you can see that our Spray-Net primer is the clear winner. The original incisions are much cleaner, with no fraying or chipping of the paint film. This demonstrates a harder, more durable paint film with powerful adhesion. And in the context of blocking tannin bleed, our primer results in tough barrier that will remain intact to keep those pesky tannins locked into place.

It’s all about process and product when tackling tannin bleed

Tannin bleed is a very common (and annoying) occurrence when it comes to painting wood kitchen cabinets- we’ve been there. While the combination of our proprietary tannin-blocking primer and strategic coatings offers the best way to revamp older oak wood kitchen cabinets without any tannin bleed, if you do decide to tackle painting your wood cabinets as a DIY project, you’re now primed —pun intended— with the tips you need to help prevent tannin bleed.

Remember to invest your time in proper surface preparation that involves not only sanding but thorough degreasing the wood surface; and look for both a primer and paint that are strategically formulated for wood and preventing tannin bleed. Our professional advice is that customization (when products are tailored to the surface being painted) always results in better results. You may be limited in color selection depending on the brand of paint, but customized coatings almost always result in better long-term performance.

Subscribe to our blog & newsletter.

This is the advantage of subscribing to our blog.