What is the best exterior paint? That is a loaded question as the word “best” is a broad adjective, and when it comes to exterior paint, the “best” depends on a myriad of factors. Our goal here is to guide your decision-making process to help give you a better idea of what you will need for your project. One thing’s for sure, the “best” exterior paint can’t simply be summarized in a quick one-sentence answer or brand name. So, buckle your seatbelt, because we’re going to take a deep, relatively technical, dive into the top things to consider when choosing the perfect exterior paint for your project:

1. How long do you expect your exterior paint job to last?

This question is almost as loaded as what is “best” since this is the primary motivation when choosing an exterior paint and with good reason. It’s not easy to do nor is it cheap so you don’t want to be doing it every year. In order to temper expectations, it’s important to understand that, at a chemical level, inert substrates (surfaces) will always hold exterior paint better than “active” or “living” surfaces such as wood. Inert surfaces allow for a more stable chemical and / or mechanical bond. This basic chemical concept means that not much will last long on wood and you’ll need to factor in regular maintenance; inert surfaces offer more promise. To narrow down the scope of this question, we’ll define durability simply as adhesion for now. Everyone knows that proper paint preparation is vital for a lasting paint job but applying the correct paint for the surface you are looking to revamp is equally as important. This leads us to our second question…

2. What surface(s) are you painting?

This is by far the most important variable to consider! Although most exterior latex paints are made to be applied on just about any surface, we all know that a jack of all trades is a master of none. At a technical level, adhesion happens when the surface tension of the paint is lower than the surface energy of the surface to be painted. In layman’s terms, if the paint does not properly coat or “wet” the surface in its entirety, you will never get the proper mechanical and / or chemical bond required for a long-lasting exterior paint job. How you apply the coating also has an impact on this but let’s not get ahead of ourselves, we’ll talk about that a bit later. Beyond adhesion, we’d need to dive a bit deeper to establish what other properties to look for on the most commonly painted exterior surfaces to ensure a a long-lasting paint job:

Siding:

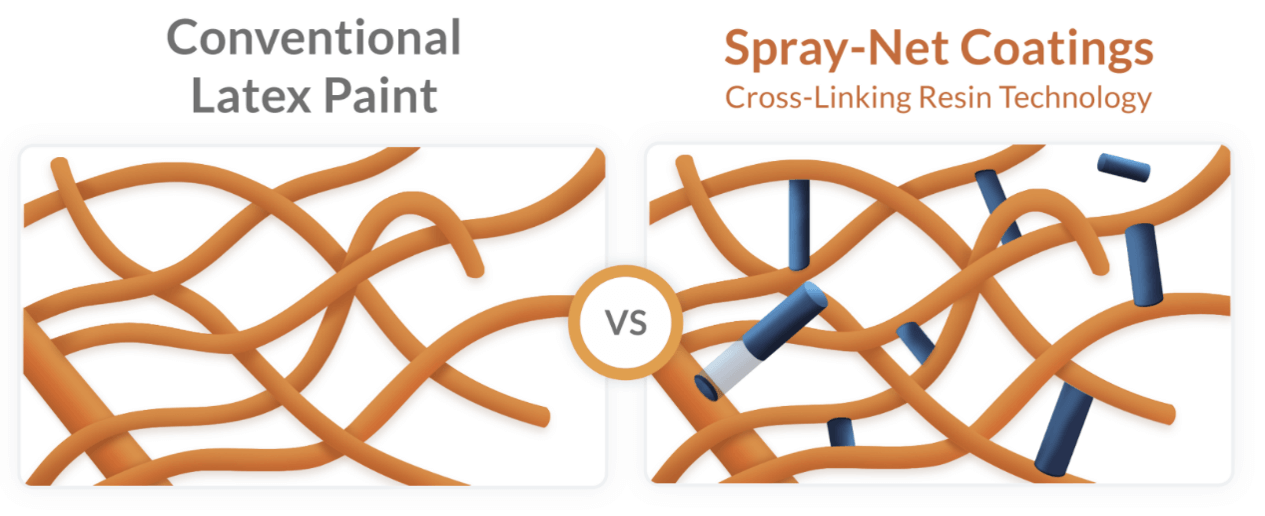

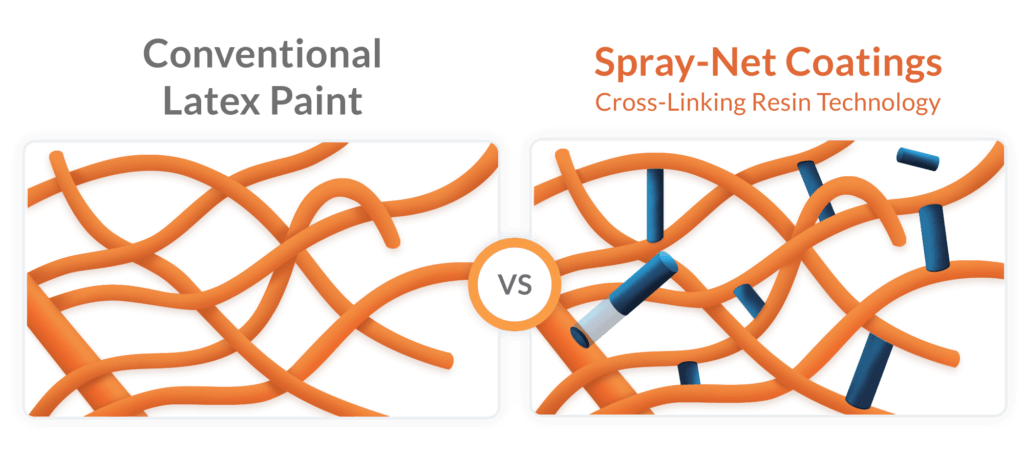

Siding paint needs to be washable yet slightly flexible. This creates somewhat of a paradox as it needs to be flexible enough not to crack but not too flexible that dirt pick-up becomes an issue (think of an elastic that can get dirty very fast when stretched). Aesthetically, you’ll want to choose a gloss that is not too flat but not so glossy that it enhances the appearance of any defects in your siding. In order to achieve these properties, the best type of conventional paint available for siding will be a self-cross-linking exterior paint. These types of resins create a tighter bond allowing for better adhesion, washing and flexibility.

Doors:

Doors are high traffic items that will require good scratch resistance. The best paint for this would be an enamel. Water based polyurethanes are an excellent choice where enhanced flexibility and fade resistance is needed (a south side facing door). Alkyd enamels could also do the trick if hardness is the primary desired property.

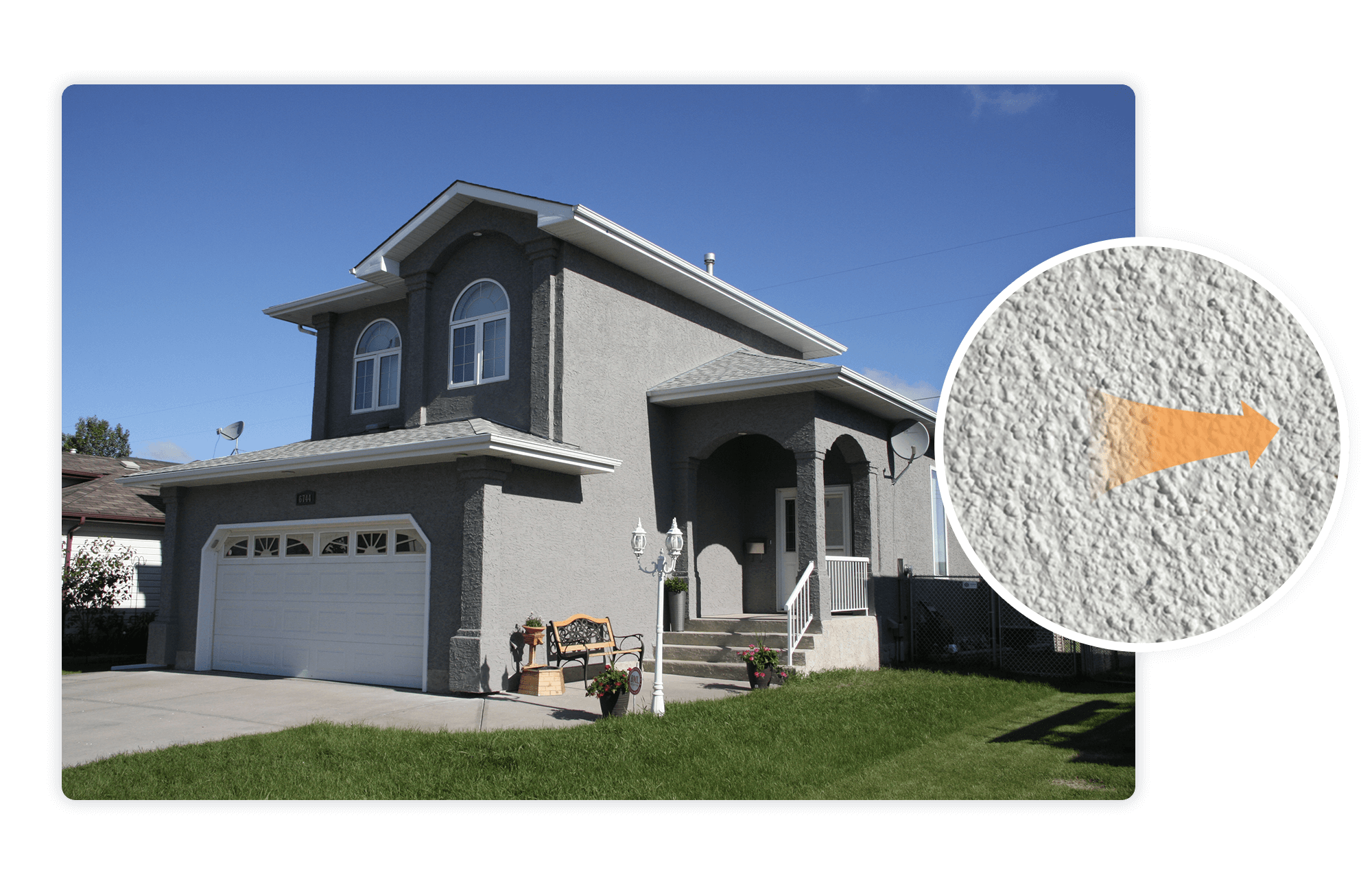

Stucco:

This is a surface that requires elasticity, breathability and, ideally, you’d want it to be washable. We say ideally because back to the elastic example, having a flexible coating that is also washable is somewhat paradoxical. Although you can use an exterior latex paint on stucco, elastomeric coatings are better suited for this type of surface. All the large paint manufacturers make these types of coatings but the challenge they face is price. Elastomeric coatings need to be applied very thick to achieve the desired coverage so you can expect a gallon to cover only between 75-100 square feet. You can see why price per gallon is critical here. Paint manufacturers will use additives such as calcium carbonate (essentially chalk) to thicken their products without drastically increasing the price. The paint then becomes less washable (good luck washing chalk) and that undesirable powdery finish will more quickly occur as the paint starts to degrade. Needless to say, make sure you do your homework and don’t purchase based on price alone.

Speaking of price…

3. What’s your budget?

There is a lot of labor required to paint the exterior of your home so our advice would be to not skimp on the product. More expensive doesn’t always mean better quality but more often than not, it does. We’d need a blog in and of itself to decipher the differences between the brands so choose the one that you prefer but don’t skimp and always get the best available product line. Most of the “big guys” have good premium exterior paint lines.

4. What equipment will you be using

Both quality and safety must be considered here because, generally, exterior painting will require work at heights. Ladders are possible however scaffolding is generally safer but more costly. Earlier we mentioned the importance of the coating to properly and entirely wet the surface to enhance adhesion, so will you be spraying on the coating? This will give you better wetting (and a thicker more even coat) over brush and roller application, not to mention a better finish, but requires a specific expertise and we’re not just saying that because we’re Spray-Net. When spraying, proper masking and technique must be used to avoid disaster. Exterior spray paint application however is but one piece of the puzzle to get the best exterior paint job so on to the next point…

5. Do you have the time?

If you’ve gotten this far, this question probably comes to mind as you start to better understand the variables to consider to get the most durable exterior paint job. Everyone knows that preparation is key to a durable exterior paint job so have you factored in the time to do this? The basics of adhesion are mechanical and / or chemical bonds and for either of these to happen, besides the other variables mentioned, a surface free of dirt and grease is required; but that’s relatively obvious. The part that is often not mentioned (or understood) is that we must increase the surface energy of the surface being painted to ensure proper wetting. This is done mechanically by scuff sanding smooth and / or glossy surfaces or, chemically, using a solvent such as acetone right before painting. We suggest doing both if, after properly washing, the surface is still shiny. Once a home is properly prepped, you’ll want to paint it within a reasonable time frame to avoid having to prep it all over again. In addition, once you start your exterior paint project, you’ll want to make sure you continue and finish within that time span, in order to avoid “lines” in your paint job. Lines occur when paint dries and there are varying thicknesses applied in certain areas; to avoid this, you’ll want to constantly maintain a “wet edge.” Enter another factor that we must layer into the equation; the weather…

6. What weather will you be painting in?

Not only must you make time to complete your project but you’ll also need to hope that the weather cooperates. Let’s recap the adhesion basics so far:

1. Make sure you have the right paint for the surface.

2. Make sure the surface is properly washed.

3. Make sure to de-gloss the surface if necessary.

Using a quality primer could be a good fail safe here. … that leads us to the last, and arguably the most crucial factor that affects exterior paint adhesion, the weather. You’ll notice many conditions that will void an exterior paints’ warranty on the can. That’s because if the paint dries too slow (cold and / or humid weather), the coating will likely sag or never fully cure and come together as one even film. If the opposite occurs and the paint dries too fast (hot and / or dry weather), the paint film will not have enough time to wet the surface and become a fully uniform film (coalescence in paint terms) and fully cover the surface. Think plastic wrap which works because it’s one full piece and that’s what you want to achieve with your paint. If there are any holes in your paint film (usually microscopic), weathering will chip away at them and compromise the job causing the ghastly p-word. PEELING! Hurts to even say it so we don’t want that! The other thing we don’t want is premature fading, which leads to our next and final point…

7. What color do you plan on painting?

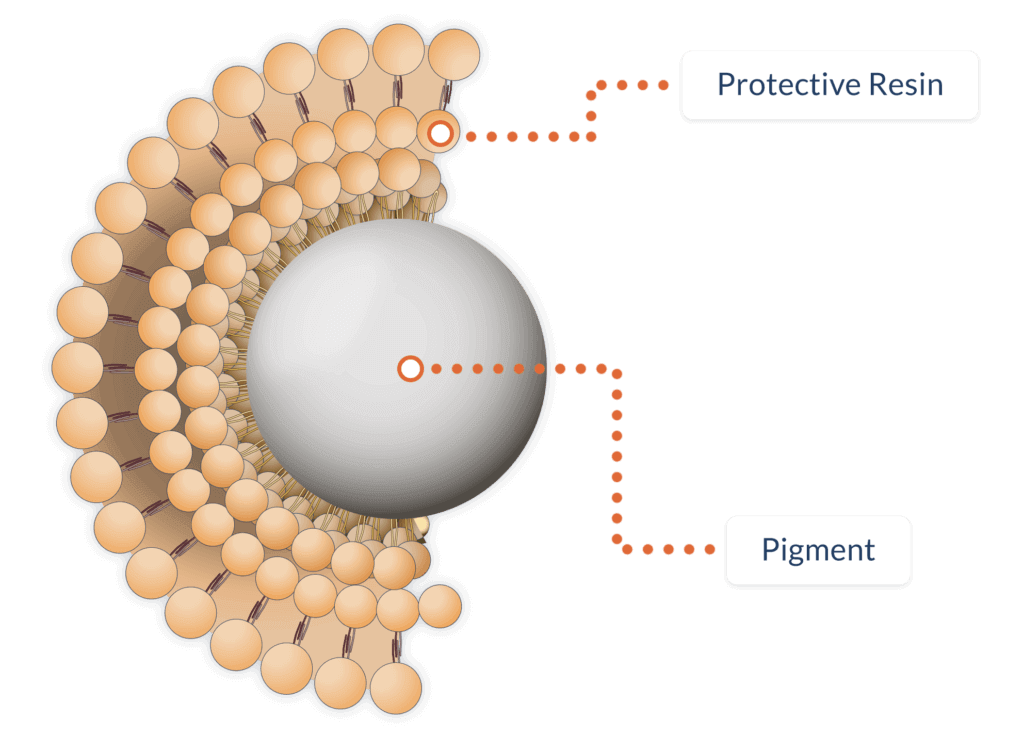

Having a long-lasting exterior paint job means one that adheres and doesn’t fade. The latter part of this sentence is a bold statement because everything fades eventually, sorry! What we can do however is delay the onset of fading; although this could also be its own blog, let’s cover the high-level variables that play a role. The most important one is the color! It is well known that reds and yellows are pigments that fade quicker than others. Specifically formulated high performance organic pigments are the first step to prolonging the life of the coating and most quality exterior paints will use varying qualities of this category of pigments (inorganic pigments are not recommended for exterior use). The second factor, and arguably the more important one, is the quality of resin used because that is what will protect the pigment from UV exposure and encapsulates the pigments. At this point you may be thinking to yourself “ok so all I need to look out for are quality pigments with a good resin and we’re good?” Not so fast! In order to achieve economies of scale, most paint retailers will tint bases of paints behind the counter in order give you that color you asked for. The issue with this is their ability to obtain the CPVC, the Critical Pigment Volume Concentration; in other words, the ideal ratio of pigment to resin. Depending on the color chosen, more (or less) pigment will be used potentially throwing off this balance and achieving that optimal point. The further away you are to the CPVC, the more rapidly fading will occur. *This can also affect adhesion as there is less resin (glue) to stick to the surface. When you glide your hands over old siding that has faded, that powder you feel is actually just free-standing pigment particles. So, you guessed it, quality matters but so does the color you choose as well as the pigment to resin ratio. Colors that have more “difficult” pigments, such as reds and yellows, will naturally fade quicker than ones that don’t. All we can do is put as many chances as possible on our side by choosing a quality product backed by a good manufacturer.

So what’s our recommendation?

Ok that was quite technical and a lot to consider, we know, but paint formulation is intricate. This is why the answer to finding the best exterior paint must attempt to cover as many bases as possible. At this point you’re probably wondering what paint brand is best. Sorry, we can’t answer that because it really depends on the purpose you need it to serve. At Spray-Net we benchmark all of our coatings on OEM factory specs using ASTM (American Standard Testing Method) tests to make sure we are surpassing the coatings standards of brand-new surfaces. If you’re looking to hire a conventional painting company or planning on painting your home yourself, consider the factors outlined above. There are some good products out there but the challenge paint retailers face is to balance paint performance, ease of application and cost in order to make products accessible to all. These constraints inevitably lead to limitations in conventional architectural paints. This is also why you’d be hard pressed to find an exterior paint warranty longer than 2 years limited by many conditions.

Realizing this, at Spray-Net we’ve reverse engineered the factory painting process and formulated our own proprietary line of coatings. We apply them using specialized spray equipment and our patented processes to truly deliver a factory durable, like-new finish directly on-site backed by our 15-year warranty. We are not in the business of retailing paint but in the business of providing the most cost-effective way to increase property value. We’ve achieved this by holistically considering all of the above variables (and other nuances) when formulating our coatings to provide homeowners with the most customized paint job possible. Our exterior paints are customized for the surface, the weather and the color; a smarter way to paint!

Subscribe to our blog & newsletter.

This is the advantage of subscribing to our blog.